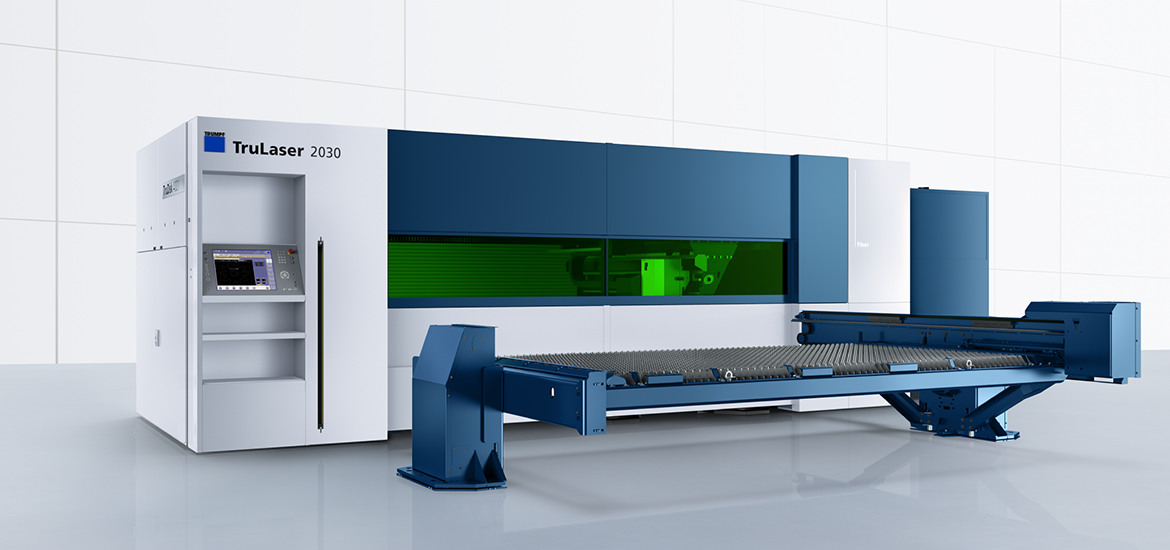

Laser Department

Utilizing cutting edge laser technology, ACC can provide a quality part, at a competitive price while providing an industry best lead time.

Fiber laser technology provides many advantages including increased speeds, minimal setup, and lower operating costs which allows ACC the ability to be a trend setter for pricing. Other advantages and capabilities are:

- Process sheet sizes up to 5’ x 10’

- Dual shuttle tables

- Prototype to Production runs

- Minimal heat affected zone

- Zero contact with material

- Tight repetitive tolerances

- Minimal taper

- Process HRPO up to 5/8” thick

- Process Stainless Steel up to 1/2” thick

- Process Alum up to 3/8” thick

- Process Galvanized and Galvanneal material

- Process Copper and Brass

The Laser Cutting Advantage

The option of laser cutting offers a broad range of compelling benefits to the capabilities of any machine shop.

Machine time and cutting tool wear can be considerably reduced with the application of laser cutting to suitable parts and features.

Laser cutting is a non-contact cutting method, which means that setup time is essentially zero. A large number of intricate parts with different geometries can be cut from the same sheet with no need to align or clamp the workpiece.

Contour location and shape can be held very close, leaving minimal margins for machining. Large contours and hole diameters are excellent opportunities for efficiency gains, as laser cutting creates the contour directly, through the thickness of the material instead of being limited to the stepwise removal processes of mechanical cutting. Very tight curve radii can also be held, reducing or eliminating the need to machine such features.

Producing a complex pattern of features is another task for which laser operations are ideally suited, offering the ability to rapidly generate any number of accurately located holes, slots, edges or other shapes to within +/-.005” of the finish dimensions and a minimal heat-affected zone. All this takes place with no need for tool changes, making it an extremely time efficient process.